How to choose the pneumatic impact ...

How to choose the pneumatic impact wrench

2013-09-22 12:00:47

_MLL.jpg) Customers are usually asking how much the torque of a pneumatic impact wrench to judge the capacity and cost.

Customers are usually asking how much the torque of a pneumatic impact wrench to judge the capacity and cost.

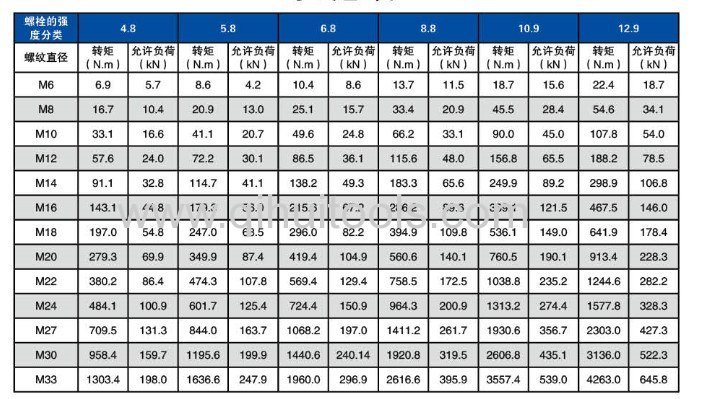

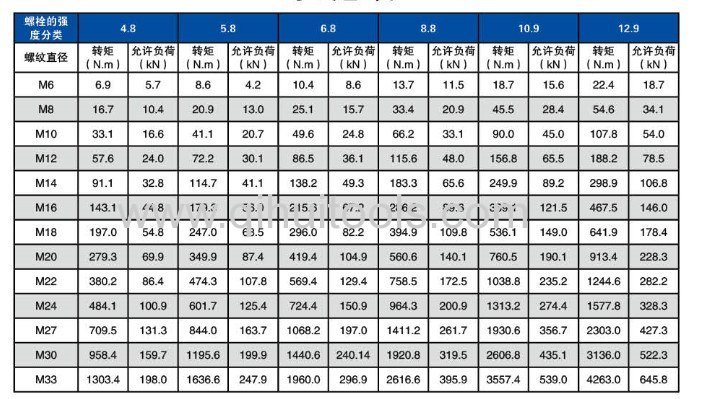

It is our responsibility to understand how about the specifications of the bolt would the customer use the pneumatic impact wrench for. The specifications are including: size of the bolt, length of the bolt, quality level of the bolt, type of the bolt. The attached format shows different specifications of the bolt needs different pneumatic impact wrenches to use.

There are many pneumatic impact wrench manufacturers in China. Brands are various. Torque's marking are of different habit, some of the torques were enlarged. For example, under 90PSI air pressure, max torque of forward rotation is 300NM, max torque of reverse rotation is 400NM, the manufacturer will mark max torque is 700NM(total torque of forward and reverse). Some other manufacturers even marked higher in order to attract the customers. While the customers need strict specifications, they want to know the real torque. If the customer buy a pneumatic impact wrench with wrong torque, it will be useless for the work. Especially for the overseas customers, they buy wrong torque pneumatic impact wrench, the return back cost will be high. So for the overseas customers, manufacturers should first honestly show the real torques and make clear what kind of the pneumatic impact wrenches would the customers like to buy.

We should also consider the working air pressure, use of the compressor, length of the air hose will also influent torque of the pneumatic impact wrenches.

Value of the torque is a relative data. Non type of the pneumatic impact wrench has highest torque. Such as in a car repair factory, many workers think the bolt to be fastened as tight as possible is the most safety. This is true for some mountain regions. If the bolt not fastened tight, after long time transportation, the bolt will easily loosen. That will cause dangerous. If you use one pneumatic impact wrench with 3000NM torque to fasten the bolt, then you need a pneumatic impact wrench with torque higher than 3000NM to loosen. With this pneumatic impact wrench to fasten again, then you need higher torque pneumatic impact wrenches to loosen. We always heard from customers: We use higher type of the pneumatic impact wrenches, but the torque still not enough. Some of the manufacturers start to make larger and larger types of the pneumatic impact wrenches. Blade length in power section enlarged from 53MM to 60MM, 70MM, 80MM, 95MM, even 105MM. Spare parts in power section is thicker. Power increased a lot, but the life time is shorter. Weight of the pneumatic impact wrench is heavier. It caused uncomfortable for using. It may hurt the user's waist. Impact section could not load such high power output. To fasten bolt with too high torque may break the bolt, cause danger. Large torque pneumatic impact wrench is not means the best choice to fasten any bolt. Torque of the pneumatic impact wrenches should not higher than bolt torque load(reference to above format).

Only a few professional customers will pay the attention to the impact structure. Take 1/2" or less pneumatic impact wrench as an example: pin clutch mechanism impact structure and twin hammer mechanism impact structure are used mostly in industrial assembly lines. Pin clutch mechanism has the advantages of continuous input, steady output, low rotation speed, fit for the same working place fasten various size of bolts. It is best for soft connection of the bolt fasten, low speed rotation provide easier change of the sockets. The life time of pin clutch mechanism remains longer. Also fit for use in auto mobile assembly workshop. Twin hammer mechanism has the advantages of strong power, high rotation speed, fit for the same working place only fasten one size of the bolt. It is best for hard connection of the bolt fasten. Motor cycle reducer assembly line requires such structure pneumatic impact wrench. Material quality of spare parts in twin hammer mechanism impact structure is very high.

It is my personal opinions in choose of pneumatic impact wrenches, waiting for your better suggestions.

Note:

Soft connection: Resistance is small at the beginning of fastening. At the moment of bolt to be fastened in the seat, the resistance increased quickly, torque increased.

Hard connection: As the bolt fastened, resistance increased slowly. After the bolt seated, the spring tight slowly, the resistance increased together.

Previous:

How to choose the right air sc

Next:

Air tools Catalogue